Energy efficiency investments by installing a cogeneration unit with heat engines and a plant for producing heat by using solar energy, at the Freidorf heating point belonging to the Local District Heating Company Colterm S.A. Timisoara

The contribution to the powerplant is: 155,8 kWp

The Local District Heating Company Colterm SA Timisoara has as object of activity: production, transportation, distribution and supply of heat power; production and sale/supply of electric power.

Initially, one of the 117 heating points, the Freidorf heating point was powered with heat through the primary heating pipe of Colterm SA Timisoara.

Being a long route, for reducing the costs of production and transportation of the heat, the profitability for activity of production and transportation of the heat and the reduction of the emissions, respectively insurance from own sources of electricity power, were analysed several variants of equipping. The solution adopted was the transformation of the Freidorf heating point into the heat station which works on natural gas where the heat for preparation of hot water for consumption to be obtained in cogeneration with heat engines and the heat for warming to be produced with heat only boilers.

In order to accomplish a new efficient source to produce power, located at Freidorf’s heating point, the power was charged directly into the distribution electrical network, thus avoiding the transit of electricity through transport networks.

Into the building of Friedorf heating point, were installed the following equipment:

– five heat only boilers type DeDietrich model 525K, with heating power installed 1392-1450 kW

– three heat exchangers with heating plates

– two heat exchangers with heating plates for hot water for consumption

– electric pumps for the movement of the primary and the secondary agent

A cogeneration group with total power (acc. ISO 3046/DIN 6271) of 1.02 MW has been installed to ensure the cogeneration of power and heat generation. It consists of two thermal motors, two electrical generators and heat exchangers needed to take over the heat produced by the engines.

The heat engines work with natural gas and through the electric generators ensures the production of power.

The system is equipped with heat pick-up plants in the engine cooling system and resulting burned gases. The heat taken is used in the primary circuit of the heat station.

The heat recovery system is interconnected with the heat production system. This ensures the functioning of the cogeneration group at the nominal regime during the operation of the heating system. In addition, after commissioning, to increase the efficiency of power, two heat exchangers have been mounted on the plates, on the cooling circuits of the intercooler.

The efficient operation of the cogeneration unit is recorded for a load of engines in margin 50-100%, the load being adjusted according to the demand for heat. Adjusting the task of the group is performed by automatically adjusting the engine load.

The cogeneration unit has the following technical characteristics:

- Electric Power 2x 500 = 1000 kW

- Heat Power 2x 518 = 1036 kW

- Electrical efficiency min. 38.6%

- Total efficiency min. 85.5%

The operating regimes of the cogeneration plant with heat engines are determined according to the demand for heat for warming and preparation of hot water for consumption. Mainly, the CET Freidorf component is the following:

- Circulation pumps 2 x 125 mc/h plus a spare electro pump. The maximum flow rate on the primary circuit is 250 MC/h

- Heat only boilers (1… 5 x 1450 kW) up to 90C

- Three heat exchangers with heating plates

- Two heat exchangers with hot water for consumption plates

- Two heat groups with heat engines connected in series with boilers, with the ceding of heat into the primary system.

- Separating valves that ensure the operation of the primary circuit in the

- with engines and boilers

- only with boilers

- only with engines

The basic regime is considered the winter regime, the period during which the heat requirement is high and therefore the two cogeneration groups work together on the nominal load.

- Power produced per hour 2 x 501 kWh = 1002 kWh

- Heat produced from

- Engine Cooling 2 x 211 kWh = 422 kWh

- Recovery from flue gases 2 x 307 kWh = 614 kWh

- Total heat groups = 1036 kWh

The additional heat required to cover the consumption is produced in heat only boilers installed in the heating plant.

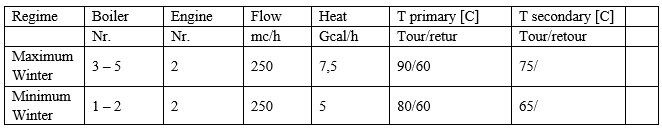

The heat production system operates at the following parameters:

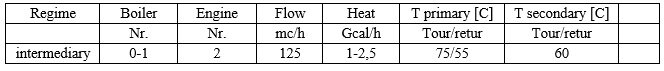

For periods of passage winter-spring respectively autumn-winter, about two months a year, the heat requirement is given by the needs of hot water for consumption and a reduced need for heating.

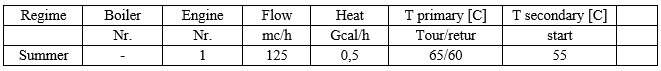

The heat production system operates at the following parameters:

Thus, following the energy analyses carried out it was observed that at CET Freidorf, in the year 2018 there were produced: 3,165 MWh Thermal Energy, of which 1,797 MWh in cogeneration, quantity that covered the consumption requirement.

The overall yield of heat and power was 80.1% for the period analysed, and the cogeneration units registered a yield of 80.4%.

Also, in order to streamline the production of heat at CET Freidorf were developed installations that use renewable energy, as an alternative to classical fuels. The renewable energy source accessible in this case was solar energy. This meant the mounting of solar panels, for the production of heat, on the roof of the terrace type of the plant, which would produce, using the existing accumulation tank, heat necessary to prepare hot water for consumption during the summer period for all consumers on CET Freidorf.

The solar-powered hot water production system is composed of solar panel collectors with fluid circulation, which transforms the electromagnetic emission of solar radiation into heat. It is transmitted to a thermic transfer fluid.

The heat transfer from the collectors to the storage tank takes place through forced circulation using a pump operated by a control system.

In the CET Freidorf enclosure a heat exchanger with stainless steel plates, PWT 200 model was installed. It ensures the transfer from solar panels to the accumulation tank. The maximum power of the exchanger is 107 kW and can retrieve the energy from 200 MP solar panel.

The installation located at CET Freidorf has the following technical parameters:

Collector are: | 191,3 m2 |

Total solar fraction: | 48% |

Annual production in field: | 118.235,1 Kwh |

Production field surface collector reported gross: | 618,2 Kwh/m2/an |

Production collector field relative to Surface: | 654,1 Kwh/m2/an |

Maximum Fuel Economy: | 12.511,7 m3 gas |

Maximum energy savings: | 131.372,3 Kwh |

Reduction of CO2 max | 30.424,3 Kg |

The estimated annual heat that can be produced with solar energy is 90 MWh, which implies a reduction in the annual consumption of natural gas of 11800 SMC.

PVPPP= QVE x η / τCS

Where:

PVPPP – Energy Saving accounted in the Virtual Power plant

QVE – The full energy saving, meaning the basis of the calculations

η – average powerplant efficiency

τCS – annual peak hours of the power plant

The contribution to the powerplant is: 155,8 kWp