KERO Energy Saving Projects 2015 – 2019

The contribution to the powerplant is: 131,3 kWp

Kimball Electronics Romania started activity in a green field facility in Remetea Mare, Timis County, Romania, in November 2015.

Since then we work to improve and certify our work environment obtaining:

- ISO 9001:2015, 12/2015

- IATF16949:2016, 04/2016

- ISO 14001:2015, 04/2017

- ISO 50001:2011, 05/2018

- ISO 45001: 2018, 06/2019

Energy saving was a priority for us since beginning, targeting to operate in a green / safe environment and, as well, to reduce our spending related to energy consumption.

Energy Saving Best Practices

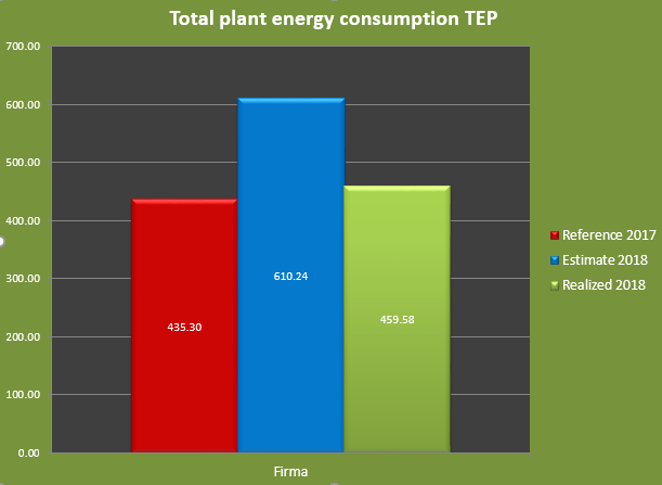

1. Temperature and humidity set points optimization

In 2018, in order to reduce energy consumption, we implemented the following changes:

- during the summer time we increased the temperature set point with 1⁰C in the production area from 23⁰C to 24⁰C

- we increased the temperature of the chilling water with 1⁰C, from 7⁰C to 8⁰C

- during the winter time we decreased the temperature set point with 1⁰C in the production area, from 23⁰C to 22⁰C

- we increased the humidity set point in the production area from 50%RH to 55%RH.

After implementation we monitored closely the effects of the changes, consulting with production people about how they feel it. There was no negative impact at all.

By doing this we were able to save 256MW (21.94TEP) per year due to electrical energy saving (summer time temperature and chiller) and 500MW (42.84TEP) per year due to gas energy saving (winter time temperature and humidity).

2. LED LIGHTING

Since beginning in 2015 we implemented LED lighting instead of standard fluorescent lamps. In our plant we use over 600 lamps, a simple math showing us a saving of about €16,000/year.

# of lamps: 610

LED lamps power: 38W/h

Fluorescent lamps: 72W/h

Power saving:

per hour: 20.7kW

per year: 119.2MW

Cost of LED lamps: €75 each

Cost of fluorescent lamps: €30 each

Yearly energy cost saving: €16,330

Pay back years: 1.7

Contribution to the Virtual Power Plant:

· Total Energy Saved: (where TEP equals to 11,36 MWh)

o Electricity: 48,7 TEP= 553,232 MWh

o Heating and gas: 90 TEP= 1.022,4 MWh

o Total: 1.575,632 MWh

PVPPP= QVE x η / τCS

Where:

PVPPP – Energy Saving accounted in the Virtual Power plant

QVE – The full energy saving, meaning the basis of the calculations

η – average powerplant efficiency

τCS – annual peak hours of the power plant

The contribution to the powerplant is: 131,3 kWp